OT Security Best Practice – Building Visibility Across Your OT Network

Operational Technology (OT) visibility isn’t just a technical checkbox—it’s a strategic necessity. You can’t protect what you can’t see, and in OT environments, that blind spot can mean the difference between smooth operations and unexpected outages, safety events, or compliance violations.

But gaining visibility in OT is complex. These environments weren’t built with monitoring in mind. They’re often made up of legacy infrastructure and complex systems that include Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controllers (PLCs) and specialized protocols.

This blog breaks down what typically gets missed, where teams should actually focus, a client example that says it all, and practical steps to get it right—because visibility isn’t just the first step toward OT resilience, it’s the one every other step depends on.

The OT Visibility Gap: What Most Teams Miss

There are two sides to the complexity in OT environments, and both IT and OT teams tend to miss different things.

IT teams often assume their tools and methods will just work in OT. But OT environments are far more fragmented and diverse. On the other side, OT teams sometimes treat their systems as too specialized for IT to understand. In reality, many OT systems are built on the same foundations—Windows machines, TCP/IP networking, and standard infrastructure—that IT knows well.

The real problem? OT teams may lack visibility into how much IT has evolved, and IT teams may not understand the constraints in OT. True progress happens when both sides bring their strengths together.

Another common issue is not understanding, misconfiguring, or not having the capability of Port Mirroring (SPAN ports) on switches. Many OT setups rely on unmanaged switches that don’t support monitoring, especially at the edge. Even when managed switches are in place, their full capabilities—like out-of-band monitoring and configuration flexibility—often go unused. The result? Either missed data or flooded systems.

What to Focus on Instead

Start with Non-Intrusive Discovery

In distributed or legacy-heavy environments with critical older devices that may have unknown flaws, active scanning is often not feasible. It’s important to use OT-aware tools that can safely identify what’s actually present—including unmanaged devices that haven’t been patched in years and systems running outdated or uncommon operating systems.

Know Your Network at Layer 2/3

Routing between network segments may or may not be enabled, and custom communication paths are often undocumented. That’s why it’s critical to have engineers who understand industrial networking down to the physical layer. This isn’t traditional IT—mistakes in OT environments can impact not just uptime, but safety.

Monitor OT-Specific Protocols

If your monitoring tools can’t read Modbus, DNP3, PROFINET, etc., they’re missing the most important data flowing across your OT environment.

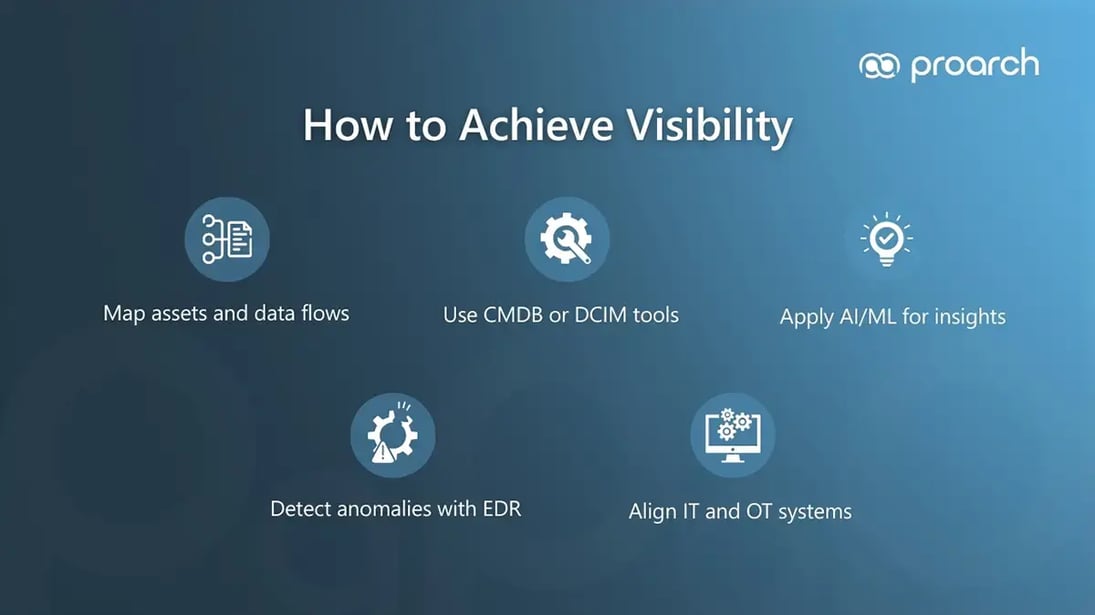

Best Practices for Building OT Visibility

- Understand Network Complexity: Start by mapping your entire OT environment—not just the obvious pieces. That means identifying every legacy system (SCADA, PLCs, DCS), every isolated subnet, and every device that’s been running quietly in the background for years. OT networks are rarely uniform, and relying on IT-centric discovery tools usually leaves gaps. Use OT-specific platforms that understand the protocols and the layout. You can’t fix, upgrade or monitor what you can’t see—and you can’t secure what you didn’t know was there.

- Configure Monitoring Correctly: Mirror ports (SPAN ports) on industrial switches are the foundation of traffic visibility. But if they’re misconfigured, you’ll either miss the critical flows or bog down the system with noise. You want accurate, non-intrusive visibility into protocols like Modbus, DNP3, and PROFINET—without interfering with operations. Get this wrong, and your monitoring stack is just checking boxes. Get it right, and you’ll see what matters.

- Adopt Zero Trust Principles: Before deploying sensors, ensure you have a complete asset inventory and a clear baseline of expected traffic behavior. Zero Trust in OT isn’t just a buzzword—it’s how you shift from reactive firefighting to proactive defense without exposing critical systems. It means continuously verifying devices, understanding traffic flows, and knowing what belongs where. Without this foundation, every alert feels like noise—and real threats can slip through the cracks.

- Prioritize Non-Intrusive Discovery: Active scanning is generally avoided in most OT environments due to the potential risks it poses, including unintended behavior in legacy systems. A safer approach involves using OT-friendly, passive discovery methods that can identify undocumented or isolated assets—such as PLCs, HMIs, or industrial PCs—without interfering with production. This is particularly valuable in distributed or aging environments where assets may have been added over time without proper documentation.

- Leverage Unified Platforms: OT environments benefit most from a unified vision. Instead of relying on separate tools for security, performance, and asset health, a unified platform—like the one provided by ProArch’s OTIMS—brings everything together in real time. It improves IT-OT team collaboration, supports proactive maintenance, reduces downtime, and turns complex data into clear, actionable insights.

Client Snapshot: What Visibility Really Delivers

One energy sector client came to us relying on a big-name OT security solution. On paper, it looked like they were covered. But once we brought in ProArch’s OTIMS platform, the reality was different.

We found critical SCADA systems with no backups. Devices running years past end-of-life. Misconfigured edge networking that created unnecessary exposure between IT and OT zones. These weren’t just inefficiencies—they were invisible unnecessary operational risks and potential NERC security events waiting to happen.

With OTIMS, they got real-time, vendor-independent insights into their whole OT landscape: device health, backup status, data flow anomalies. Bonus? Their finance team could finally make capex decisions grounded in lifecycle data—not guesses. It turned their visibility gap into a planning advantage.

Quick Tip

“Visibility is the foundation of OT security. Get it wrong, and everything built on top of it is shaky.”

Visibility That Goes Beyond Compliance

Many organizations turn to ProArch’s OT Insights & Managed Services platform for compliance—specifically for Internal Network Security Monitoring (INSM) under NERC standards. But OTIMS delivers far more than regulatory visibility.

It offers real-time insights into security events, device health, operational performance, and early warning alerts. It becomes the “eyes and ears” of your OT infrastructure—not just for one vendor, but across your entire environment—showing what’s connected, how it’s behaving, and what’s changing.

And that’s where the real value is: OTIMS helps teams bridge the gap between cybersecurity, reliability, and operational efficiency. It removes the mystery around OT systems and provides a basis for future planning. It allows your people to act faster, prioritize better, and make decisions with actual context.

Ready to stop flying blind? Talk to us and let’s get your visibility strategy dialed in.

Director of Marketing Rebecca leads ProArch's marketing efforts, seamlessly blending technology and storytelling to assist clients in their buying journey. She is dedicated to presenting technological solutions in a compelling manner that drives significant growth for the company. Collaborating closely with sales, engineering, leadership, and HR teams, Rebecca sets the strategic vision for ProArch and ensures alignment across the organization. Her strategic, visionary, and detail-oriented approach shapes ProArch’s brand to be synonymous with reimagining technology to achieve business objectives.